The whole cycle is timed by pulses of the PWM signal, which is derived from the internal oscillator.

#Dc motor with pwm avr codevision avr driver

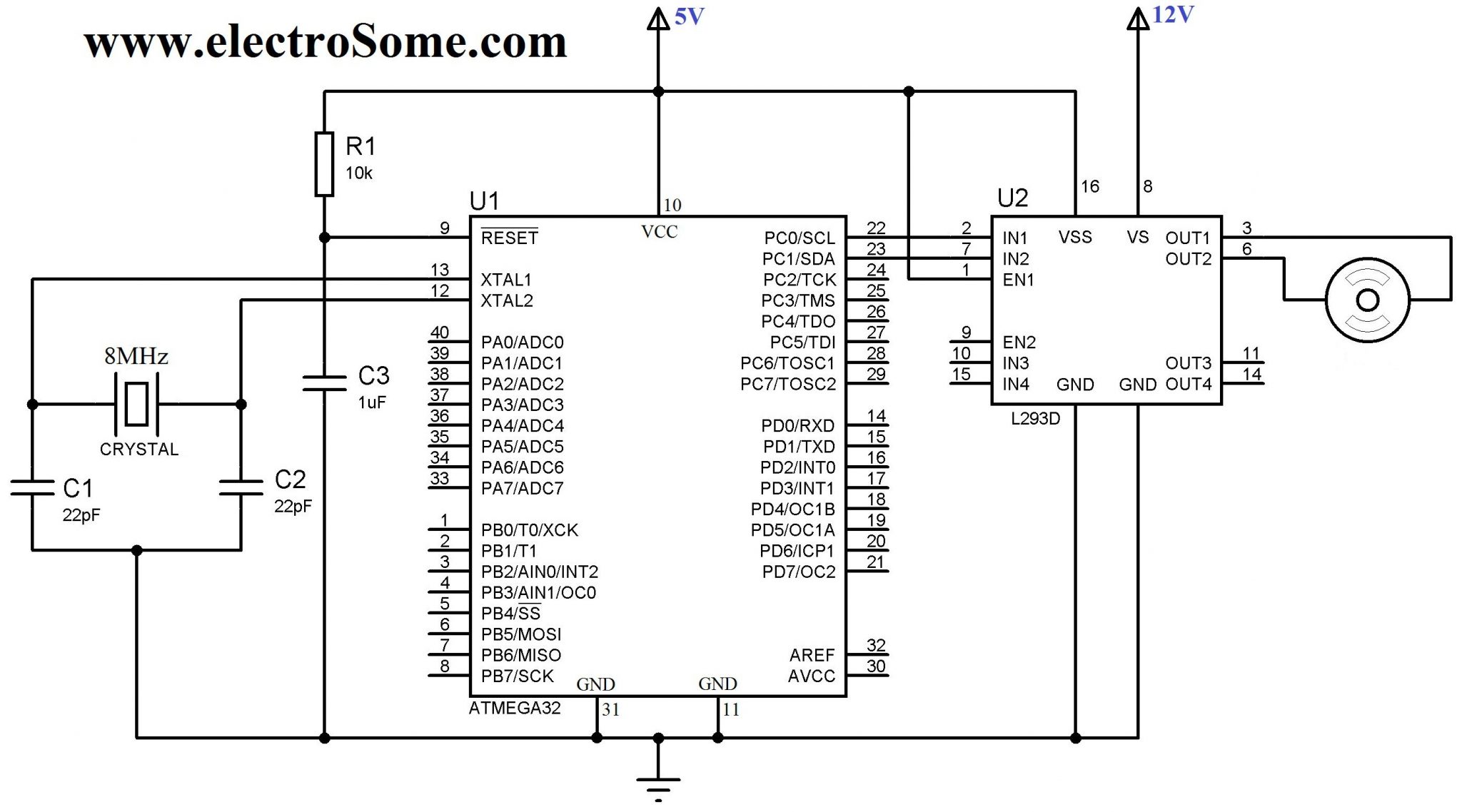

The motor control logic section regulates the current by opening and closing the specific MOSFETs of the H-Bridge, allowing the current through the coils to rise to a certain point (charging), to circulate between the coils and the driver until a specified point of time is reached (slow decay), and then to return the remaining energy to the power supply (fast decay). This results in better efficiency, less heat dissipation, and provides control over the torque, direction, and speed of the motor.Įach motor is driven by the internal H-Bridge, which is controlled by the control logic section of the TB67H400AFTG IC. The TB67H400AFTG utilizes two sensing resistors (one for each channel) in combination with an internally generated PWM signal, to regulate the current through the motor. Therefore, a specialized driver circuit is required. There are two output terminals used to connect DC motors, and a power supply input terminal, where the external PSU can be connected, with respect to the polarity marked on the Click board™ itself (bottom side).īrushed DC motors are typically made with only two conductors, used to supply the motor with power, so even controlling the direction can be challenging in some situations. A short-circuit at the output terminal may damage the Click board™. Although the TB67H400AFTG driver has both thermal and overcurrent protection, it is just a temporary measure. The optimal voltage that should be used is 24V. Before attempting to connect a single DC brushed motor, please refer to the datasheet of the TB67H400AFTG for precise connection instructions.ĭC MOTOR 7 click requires an external power supply for operation. This IC offers an additional, alternative mode, where it can use its internal H-Bridges in parallel, offering twice as much power for a single motor. However, many external parameters affect both the maximum voltage and the current specifications, especially when the connected load is of a complex nature, such as the DC motor. Due to a very low ON resistance of the MOSFETs, it can theoretically deliver up to 4A of current to the connected load. This IC uses a proprietary BiCD manufacturing process, allowing this IC to be powered by a wide range of supply voltages, from 10V up to 47V. The main component of DC MOTOR 7 click is the TB67H400AFTG, a PWM chopper-type brushed DC motor driver, produced by Toshiba. However, it can also be used for driving DC brushed motors in some more demanding applications, including air or water pumps, air condition systems, ventilation systems, handheld tools, etc. Equipped with the specialized motor driver IC, DC MOTOR 7 click can be used for any application that requires a simple and reliable dual DC motor support, including various RC cars and boats, small to medium-sized robots, drones, and similar applications.

0 kommentar(er)

0 kommentar(er)